Grasping In-Mold Decorations: Strategies, Fads, and Best Practices for Optimal Outcomes

In the world of production, the art of in-mold decorations stands as an essential aspect of product style and manufacturing. In-Mold Decorations. By diving into the methods, fads, and ideal techniques that underpin effective in-mold decor processes, services can open a world of opportunities that not just raise the aesthetic appeal of their items however likewise enhance manufacturing effectiveness and boost consumer interaction.

Product Choice

Material choice is an important element of understanding in-mold decors, as it straight affects the high quality and toughness of the last product. When choosing materials for in-mold decorations, it is vital to consider variables such as compatibility with the molding procedure, the preferred aesthetic outcome, and the environmental problems the product will encounter. Polycarbonate materials like abdominal muscle, polycarbonate, and polypropylene are generally made use of for in-mold designs because of their versatility and capacity to attain elaborate designs. These materials use outstanding moldability, enabling makers to create intricate shapes and patterns with precision.

In addition, the selected product should have good bond residential or commercial properties to make certain that the decoration adheres securely to the substrate during the molding procedure. Attachment between the product and the decor is crucial for stopping delamination and making certain long-lasting visual charm. In addition, materials with high warm resistance are favored for in-mold decors, especially for products that will be subjected to raised temperatures during their lifecycle. By thoroughly choosing the proper product for in-mold decors, suppliers can boost the total top quality and durability of their products, meeting the expectations of both end-users and customers.

Layout Technology

A crucial consider advancing the field of in-mold designs is the constant exploration and implementation of design development techniques. Design technology plays a critical function in improving the visual allure, capability, and total high quality of products made making use of in-mold design processes. By integrating ingenious layout elements, suppliers can differentiate their items on the market, bring in customers, and remain in advance of rivals.

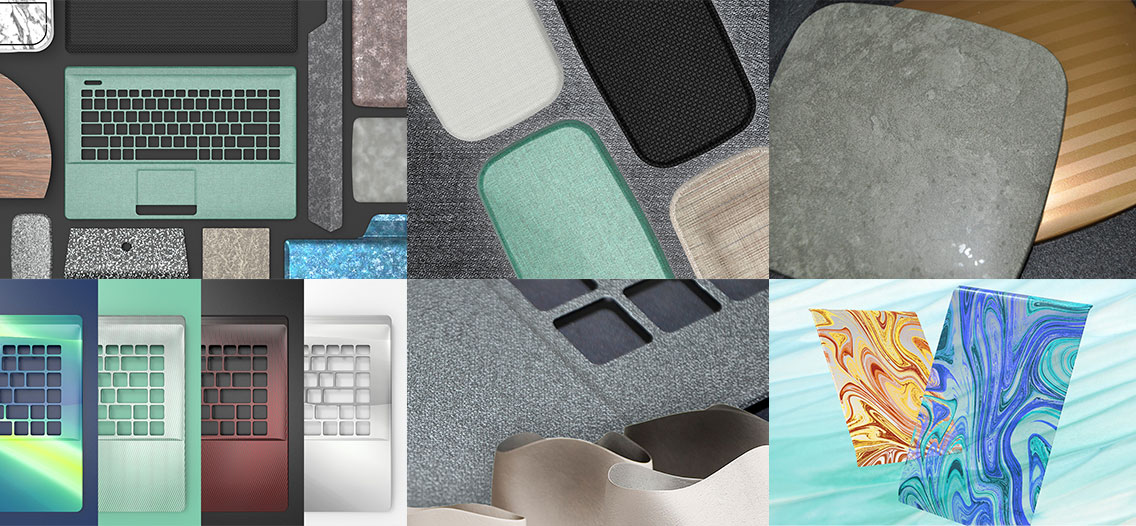

One of the key facets of style innovation in in-mold decors is the combination of detailed patterns, appearances, and graphics that were previously testing to accomplish with typical design methods. Advanced innovations such as 3D printing and digital layout tools make it possible for designers to develop complex and detailed layouts that can be effortlessly moved onto molded components. Additionally, using vibrant shades, metallic surfaces, and unique effects like gloss or matte appearances can further raise the visual allure of in-mold embellished items.

Furthermore, style technology extends past appearances to encompass practical improvements such as ergonomic shapes, integrated functions, and personalized elements that provide to specific user requirements. By welcoming layout innovation, suppliers can unlock new opportunities for creative thinking, personalization, and product distinction in the affordable landscape of in-mold decors.

Production Performance

Effective production processes are essential for converting the ingenious styles developed in the area of in-mold designs into high-quality ended up products that satisfy market demands and customer expectations. In the world of in-mold designs, production performance encompasses numerous essential aspects that add to the overall success of the production process.

Additionally, executing automation and robotics in the assembly line can substantially improve performance by improving recurring tasks and lowering the margin of mistake. Automation not only speeds up the production process yet likewise enhances accuracy and repeatability, causing a more high-quality and consistent end product. Adopting lean manufacturing concepts, such as just-in-time supply management and waste reduction methods, can even more boost manufacturing efficiency by lessening downtime and maximizing resource usage. Generally, an all natural approach to manufacturing efficiency is critical in making the most of the capacity of in-mold design strategies and attaining ideal outcomes in the affordable market landscape.

Quality Assurance Measures

What are the essential techniques for guaranteeing rigid quality control procedures in the world of in-mold designs? Quality control steps are vital in in-mold decor procedures to ensure the manufacturing of remarkable and high-grade ended up items.

Utilizing sophisticated innovations such as automated examination systems can additionally improve the high quality control process by supplying precise and trustworthy data for evaluation. These systems can detect blemishes that may be missed by manual inspections, therefore improving total item quality and consistency.

Regular training and growth programs for workers included in the in-mold design process can likewise add to maintaining high-quality criteria. By educating team on ideal methods, quality expectations, and the value of interest to detail, firms can promote a society of top quality awareness throughout the company.

Customer Allure

To enhance the bankability of in-mold decoration items, providing and understanding to consumer preferences play an essential role in Visit Website identifying their charm and success. Consumer allure in in-mold designs is affected by numerous elements, consisting of style visual appeals, color choices, longevity, and total functionality. Consumers are progressively seeking customized and one-of-a-kind products that reflect their uniqueness and style. Providing personalization choices such as tailored layouts, shade variants, and textural elements can considerably enhance the appeal of in-mold decor products.

Verdict

In-mold decors use a effective and versatile means to boost product appearances. By carefully selecting materials, embracing innovative styles, maximizing manufacturing procedures, applying top quality control measures, and focusing on customer appeal, makers can accomplish ideal results. It is important for business to constantly adapt and improve their methods to remain competitive on the market. In-Mold Decorations. Grasping in-mold decorations requires an all natural strategy that takes into consideration all facets of the production procedure to make sure success.

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of product style and production. Style development plays an essential function in boosting the visual charm, functionality, and total quality of items produced making use of in-mold decor procedures.One of the essential facets of style innovation in in-mold designs is the integration of complex patterns, textures, and graphics that were formerly challenging to my review here attain with traditional decor methods.Effective manufacturing processes are important for translating the ingenious layouts developed in the area of in-mold decorations into high-grade completed items that satisfy market needs and customer expectations. Using customization choices such as tailored layouts, color variants, and textural aspects can considerably improve the allure of in-mold design items.